Membranes, snap domes and bursting discs

Membranes and bursting discs are used in a variety of applications. Material specifications are therefore extremely diverse. The main applications for the thin strips of Lamineries MATTHEY in this sector can be divided into three groups: pressure sensors, bursting discs and snap switches.

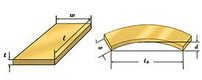

Precision strip used in membranes for pressure sensors must have a blemish-free surface, should be highly formable, absolutely impermeable, dimensional uniformity and corrosion-resistant to the ambient medium. Lamineries MATTHEY also offers solutions in the area of safety engineering. Application examples include bursting discs, decoupling systems to protect against explosion, flames and sparks, explosion pressure absorption systems and flame and detonation. The main characteristics of the thin strip and foil used in these applications are dimensional uniformity, corrosion resistance in the ambiant environment and constant mechanical properties. The airbag gas generator in an automobile which enables the bag to inflate in a fraction of a second in case of an accident is a good example for the application of such cold-rolled products. The disc which prevents overpressure must burst in a pre-defined fashion to enable a controlled deflation of the airbag, is an essential component which must be fully functioning during the whole life of the vehicle.

In the area of safety engineering and membranes for pressure sensors, Lamineries MATTHEY is one of the principal suppliers of precision strip and foil. Please find below a selection of alloys for this field of application:

| Nickel and Nickel alloys | Technical file |

|---|---|

| Ni - Nickel 200 / 2.4068 / N02200 |  Nickel_v22E.pdf

Nickel_v22E.pdf |

| Ni - 2.4061 / 2.4060 / 2.4066 / Nickel 201/200 / N02200 / N02201 |  Nickel_v22E.pdf

Nickel_v22E.pdf |

| Ni - High purity nickel 99.8% / 2.4061 / N02201 |  Nickel_v22E.pdf

Nickel_v22E.pdf |

| NiCr15Fe - (Inconel) Alloy 600 / ~ 2.4816 / N06600 |  Alloy600_v25E.pdf

Alloy600_v25E.pdf |

| NiCr19Fe18.5Mo3 Alloy 718 (Inconel, Hastelloy) / N07718 / 2.4668 |  Alloy718_v22E.pdf

Alloy718_v22E.pdf |

| NiCr21Mo14W Alloy C-22 (Inconel, Hastelloy) / N06022 / 2.4602 |  HastelloyC-22_v26E.pdf

HastelloyC-22_v26E.pdf |

| NiCr22Mo9Fe5 - (Inconel)Alloy 625 / ~ 2.4856 / N06625 |  Alloy625_v24E.pdf

Alloy625_v24E.pdf |

| NiCu30Fe - (Monel) Alloy 400 / 2.4360 / N04400 |  NiCu30Fe-Monel_v22E.pdf

NiCu30Fe-Monel_v22E.pdf |

| NiMo16Cr15W - (Hastelloy) All. C-276 / 2.4819 / N10276 |  HastelloyC276_v24E.pdf

HastelloyC276_v24E.pdf |

| Stainless steels | Technical file |

| 1.4401 - Stainless steel / X5CrNiMo17-12-2 / ~ AISI 316 |  1.4401-316_v22E.pdf

1.4401-316_v22E.pdf |

| 1.4404 - Stainless steel / X2CrNiMo17-12-2 / ~ AISI 316L |  1.4404-316L_v22E.pdf

1.4404-316L_v22E.pdf |

| 1.4435 - Stainless steel / X2CrNiMo18-14-3 / ~ AISI 316L |  1.4435-316L_v22E.pdf

1.4435-316L_v22E.pdf |

| 1.4571 - Stainless steel / X6CrNiMoTi17-12-2 / ~ AISI 316Ti |  1.4571-316Ti_v22E.pdf

1.4571-316Ti_v22E.pdf |

| M 350 - Precipitation hardening stainless steel / S35000 / AISI 633 | |

| Beryllium Copper and Beryllium Nickel | Technical file |

| CuBe2 - Alloy 25 / C17200 / CW101C |  CuBe2-All.25-P_v22E.pdf

CuBe2-All.25-P_v22E.pdf |

| CuBe2 - Alloy 190 mill hardened / C17200 / CW101C |  CuBe-Alloy190_v22E.pdf

CuBe-Alloy190_v22E.pdf |

| NiBe2 - Alloy 360 / N03360 |  NiBe-Alloy360_v22E.pdf

NiBe-Alloy360_v22E.pdf |

| Coppers and low alloyed coppers | Technical file |

| Cu-ETP - E Cu 58 / Cu a1 (Cu99) / CW004A / C11000 |  Cu-ETP_22E.pdf

Cu-ETP_22E.pdf |

| Cu-OF - OF-Cu / Cu c1 / CW008A / C10200 |  Cu-OF_v22E.pdf

Cu-OF_v22E.pdf |

| Cu-OFE - OFE-Cu / C10100 |  Cu-OFE_v22E.pdf

Cu-OFE_v22E.pdf |

| Copper alloys | Technical file |

| Cu56Ni25Zn19 - ARCAP® AP1C / C79360 |  ARCAP_AP1C_v26E.pdf

ARCAP_AP1C_v26E.pdf |

| Cu64Ni25Zn11 - ARCAP® AP1 |  ARCAP_AP1_v26E.pdf

ARCAP_AP1_v26E.pdf |

| CuNi12Zn24 - Nickel Silver (M12) / CW403J / ~ C75700 |  CuNi12Zn24_v22E.pdf

CuNi12Zn24_v22E.pdf |

| CuNi18Zn20 - Nickel Silver (M18) / CW409J / ~ C76400 |  CuNi18Zn20_v22E.pdf

CuNi18Zn20_v22E.pdf |

| Other specialties | Technical file |

| Alloy 902 (Thermelast®) / N09902 / ~ Ni-Span-C Alloy 902® |  Thermelast_v25E.pdf

Thermelast_v25E.pdf |

| Ti - Titanium Grade 1 / 3.7025 / R50250 |  Titane-Gr1_v22E.pdf

Titane-Gr1_v22E.pdf |

| Ti - Titanium Grade 2 / 3.7035 / R50400 |  Titane-Gr2_v22E.pdf

Titane-Gr2_v22E.pdf |

Mechanical strength, long life expectancy and high corrosion resistance play an important role in the design of snap switches (snap domes) which are increasingly used in key boards and control panels. The broad range of spring materials with narrowly defined chemical compositions offered by Lamineries MATTHEY allows the design of of snap domes with a practically constant force-deformation ratio across the working temperature range and which offer above standard life expectancy. Please find below a selection of those alloys we supply for this application:

Other alloys are also available. There is a list with all presently available alloys.

| Stainless steels | Technical file |

|---|---|

| 1.4310 - Stainless steel / X10CrNi18-8 / ~ AISI 301 |  1.4310_v22E.pdf

1.4310_v22E.pdf |

| 1.4310.4 - Stainless steel / X10CrNi18-8 / ~ AISI 301 |  1.4310.4_v22E.pdf

1.4310.4_v22E.pdf |

| Beryllium Copper and Beryllium Nickel | Technical file |

| CuBe2 - Alloy 25 / C17200 / CW101C |  CuBe2-All.25-P_v22E.pdf

CuBe2-All.25-P_v22E.pdf |

| CuBe2 - Alloy 190 mill hardened / C17200 / CW101C |  CuBe-Alloy190_v22E.pdf

CuBe-Alloy190_v22E.pdf |

| Copper alloys | Technical file |

| CuSn6 - Phosphor Bronze, 6% / CW452K / C51900 |  CuSn6_v22E.pdf

CuSn6_v22E.pdf |

| CuSn8 - Phosphor Bronze, 8% / CW453K / C52100 |  CuSn8_v22E.pdf

CuSn8_v22E.pdf |

| CuZn23Al3Co - Special Brass / CW703R / ~C68800 |  CuZn23Al3Co_v22E.pdf

CuZn23Al3Co_v22E.pdf |

| Other specialties | Technical file |

| CuNi15Sn8 - BrushForm® 158 / ToughMet 3 / C72900 |  BrushForm158_v22E.pdf

BrushForm158_v22E.pdf |

| CuNi15Sn8 - BrushForm® 158 mill hardened (Toughmet 3) / C72900 |  BrushForm158_v22E.pdf

BrushForm158_v22E.pdf |

| CuNi9Sn6 - Niclafor® 1000 / C72700 |  Niclafor-1000_v25E.pdf

Niclafor-1000_v25E.pdf |

| CuNi9Sn6 - Niclafor® 1000 mill hardened/ C72700 |  Niclafor-1000_v25E.pdf

Niclafor-1000_v25E.pdf |

| Duratherm® 600 / 2.4781 |  Duratherm_v25E.pdf

Duratherm_v25E.pdf |

| Aluminium alloys | Technical file |

| AlCuMg2 - (Avional 150) / AW-2024 / AA2024 |  AlCuMg2_v24E.pdf

AlCuMg2_v24E.pdf |

| AlMg3 - (Peraluman 300) / AW5754 |  Peraluman_v22E.pdf

Peraluman_v22E.pdf |

| AlMg4.5Mn (Peraluman 460) / AW-5083 / AA5083 |